Keeping track of assets across multiple buildings is rarely as tidy as the org chart suggests. Manuals end up in shared drives with vague names, warranty dates live in PDFs that never surface on time, and service notes sit in someone’s inbox long after the technician has left the site. That fragmentation slows response times, increases repeat visits, and drives up operating costs. SIM-ON’s AI asset recognition tackles that mess at the source by converting your Matterport digital twin into a living, location-aware asset directory. Instead of typing everything in by hand, SIM-ON analyzes the 3D model, recognizes common equipment, and proposes structured records that sit exactly where the device exists in space. What used to require several systems and a scavenger hunt becomes a single, visual workflow that anyone on the team can follow.

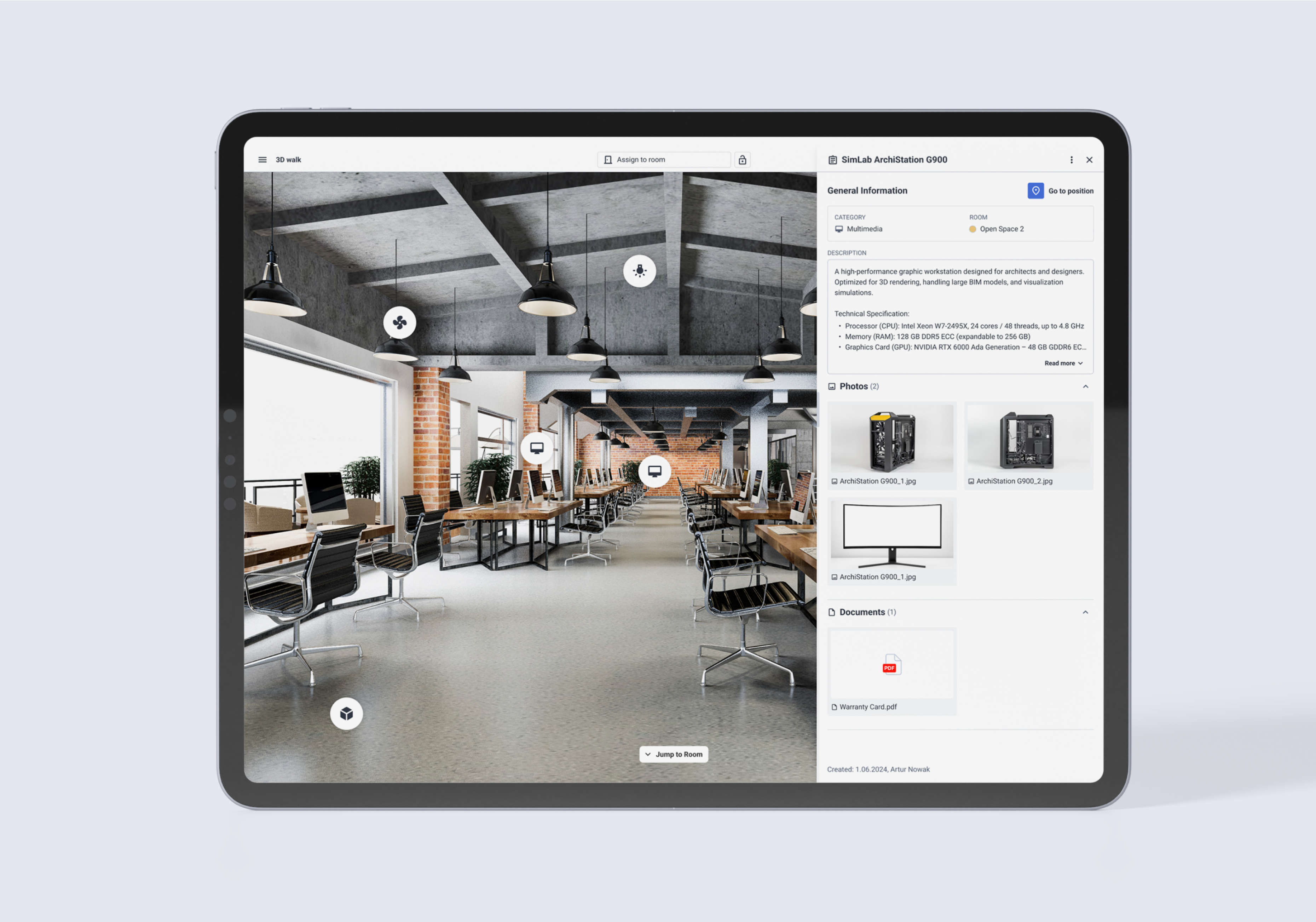

At a practical level, AI asset recognition examines each scene of the Matterport model and looks for objects that match known equipment types. When it finds a likely candidate, SIM-ON can create a record with the basics that typically matter most on day one: a precise position in the twin, a sensible category, and core descriptive fields. From there you enrich the record with documents, images, and notes that are already scattered across your organization. The difference is not only the automation of the first step. It is the permanent link between the record and its true location. Technicians are not browsing rows in a spreadsheet or clicking through nested folders. They are looking at the actual room, the real panel, and the label that was captured in the scan. That spatial context removes guesswork and shortens the path from alert to action.

Spatial context also changes how teams collaborate. A supervisor who assigns work can open the twin, navigate to the mechanical room, and review the timeline of inspections and repairs pinned to the device in question. A contractor who has never visited the site can orient in seconds because the path to the asset is visible in the model. When the job is done, proof of work can be added as a photo, a short voice note, or a simple status update that becomes part of the asset’s history. Over time the record builds into an audit trail that supports compliance checks, warranty claims, and internal quality reviews without extra effort. The twin becomes a shared language for owners, facility teams, and vendors. Everyone sees the same space and talks about the same object.

The business impact shows up in small moments that compound. A leak alarm that once triggered a long exchange of emails becomes a quick navigation in the model and a targeted assignment to the right person. A warranty dispute that would have required digging through email can be resolved with a timestamped history and photos captured at the location. Even onboarding improves. New technicians learn faster because they can study the site remotely, understand where equipment is placed, and review maintenance patterns before their first day on the job. These gains do not require new headcount or a lengthy transformation program. They flow naturally from putting data back into the spatial context where the work happens.

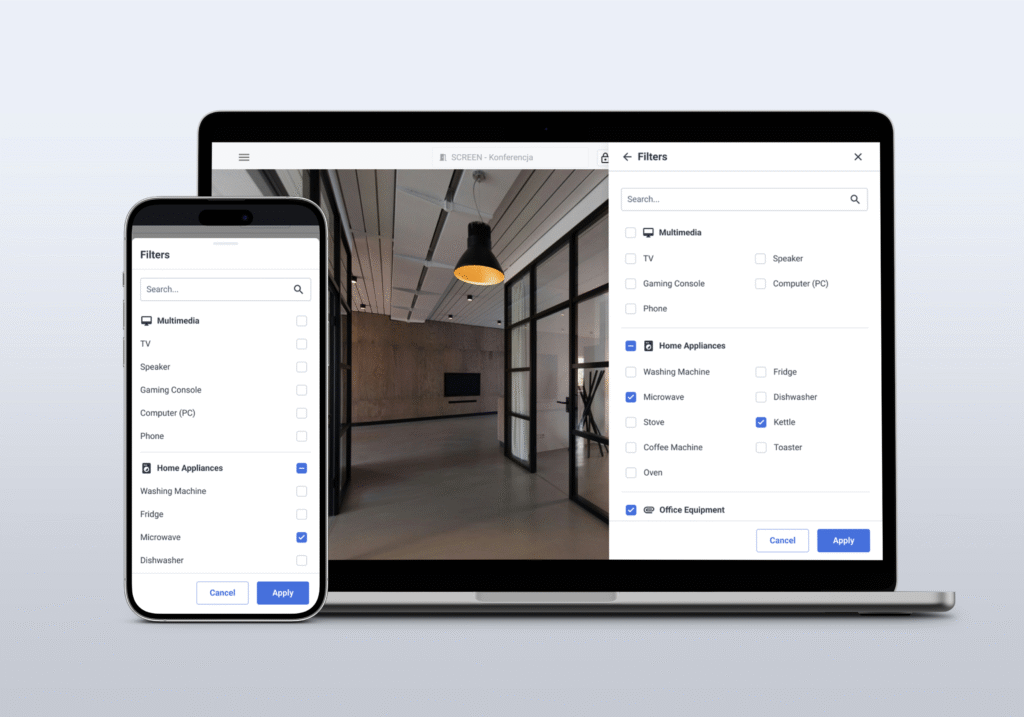

Different property types feel these improvements in different ways. Office and commercial portfolios benefit from the repeatable nature of their equipment. When devices follow a consistent pattern from floor to floor, recognition is fast, and maintenance profiles can be applied in a predictable way. Industrial and logistics facilities see value in faster diagnostics and fewer repeat visits, because even small reductions in downtime translate into meaningful savings. Hospitality operations appreciate the ability to align housekeeping, engineering, and vendors around a single view of rooms and back-of-house equipment, which shortens response times and keeps guest experience smooth. Education and healthcare campuses, spread across many buildings with strict compliance requirements, gain audit-ready histories without adding administrative overhead. The common thread is clear data, tied to a clear place, available to everyone who needs it.

Rolling out AI asset recognition does not require a multi-year roadmap. Most teams start small and scale with confidence. A typical approach is to select one facility and focus on a single category such as HVAC. You import the Matterport space into SIM-ON, run recognition, and review the suggested assets. Once the initial pass looks solid, you attach the essentials: manuals, one-line diagrams, warranty statements, and a short set of operating notes that would help the next person in the room. Then you define a simple maintenance profile and assign responsibilities. A short training session with a few technicians and a supervisor is usually enough to make the twin the first place they look and the last step before closing a ticket. When the team starts saving time finding equipment and documenting work, you connect SIM-ON to your system of record, for example IBM Maximo, so asset IDs and ticket status stay aligned. With that backbone in place, you expand to additional categories and facilities at a pace the organization can absorb.

Day-to-day use is intentionally straightforward. A supervisor planning the week filters the view in SIM-ON to show the air handlers on a particular level, checks each asset timeline for overdue tasks, and assigns a vibration check to the morning shift. The technician receives a notification, opens the twin on a tablet, and follows the visual route to the unit. If a belt shows wear, a quick photo and a short voice note capture the condition and suggested replacement. SIM-ON adds that information to the asset and, when connected to an EAM, pushes the relevant work ticket to the system that handles parts, labor, and approvals. At the end of the week, exporting a PDF that summarizes completed tasks with timestamps and reference images is a single step. The paperwork writes itself because it is captured at the source.

Accuracy and control matter whenever AI enters an operational workflow. Recognition quality improves with good scanning practices. Even lighting, clear views of labels where possible, and consistent coverage across rooms make a difference. Uncommon or custom equipment will still require a manual touch, but that effort can be focused where automation is least reliable rather than spread across everything. The right governance keeps the data trustworthy. SIM-ON supports role-based permissions so outside vendors see only what they need. Every change is tracked with a timestamp and a user identity. If you link assets to IBM Maximo or another EAM, the financial and compliance records remain authoritative while SIM-ON serves as the visual front end. Ownership of data stays with you at all times.

AI asset recognition is a strong on-ramp, but SIM-ON’s value does not stop at identification. Once assets live in the twin, the platform brings additional operational layers into the same view. IoT and building automation data can be visualized where it matters, whether that is a KNX network, a NETxAutomation gateway, or other multi-standard frameworks. Tickets and inspections can be created in the space that needs attention, with location-aware checklists that ensure consistent execution. Scenes can combine sensors and devices from different vendors into coordinated actions that respond to conditions in real time. For organizations that use STAGES during construction, the handover to SIM-ON at commissioning is smooth, so the as-designed and as-built story carries into operations without losing context. The benefit is alignment. Everyone works from the same picture, whether they are building, maintaining, or upgrading the property.

It is worth pausing on what success looks like after a few months. Teams report that less time is spent searching and more time is spent fixing. Supervisors find that audit trails are complete without additional administrative work. Vendors onboard more quickly because the site is obvious and the documentation sits beside the asset. Compliance improves because recurring tasks are visible, assigned, and tracked in a way that auditors can understand. Turnover hurts less because knowledge lives in the model, not just in a senior tech’s memory. Those outcomes are not abstract. They show up as shorter ticket durations, fewer return visits, and fewer surprises during inspections. Over a portfolio, those saved minutes and avoided mistakes add up.

Getting started is simple if you already capture with Matterport. Connect a space to SIM-ON, run recognition on one category, attach the documents you already have, and create your first maintenance schedule. Invite a small pilot group to use the twin for two weeks and measure time to locate equipment and time to close. If you are evaluating an EAM connection, schedule a session to link SIM-ON with IBM Maximo so asset IDs and tickets flow the way your finance and compliance teams require. If your capture quality has been uneven, update your guidelines and rescan critical areas to improve recognition. None of these steps are heavy lifts, and each one nudges the organization toward a more reliable, more transparent way of working.

The promise of digital twins has always been to give teams one place to see and act on what matters in a building. AI asset recognition in SIM-ON moves that promise from a concept to an everyday practice. It uses the model you already capture to build the asset structure you need, then anchors documents, tasks, and history to the exact place where work happens. Skilled people and clear processes still do the real work. The difference is that they spend less time hunting for information and more time delivering results.

If you want to see the workflow end to end, watch a short demo and test SIM-ON on a space of your own. If you prefer a guided session with your data and your team, we are ready to walk through the setup and first use cases with you. The path from scan to working asset system is shorter than most organizations expect, and the payoff begins on day one.