The integration of Maximo with the asset management function in SIM-ON’s Digital Twin environment offers many benefits, especially in the context of Enterprise Asset Management (EAM) and maintenance operations:

Improved Data Visualization and Understanding

Spatial Context

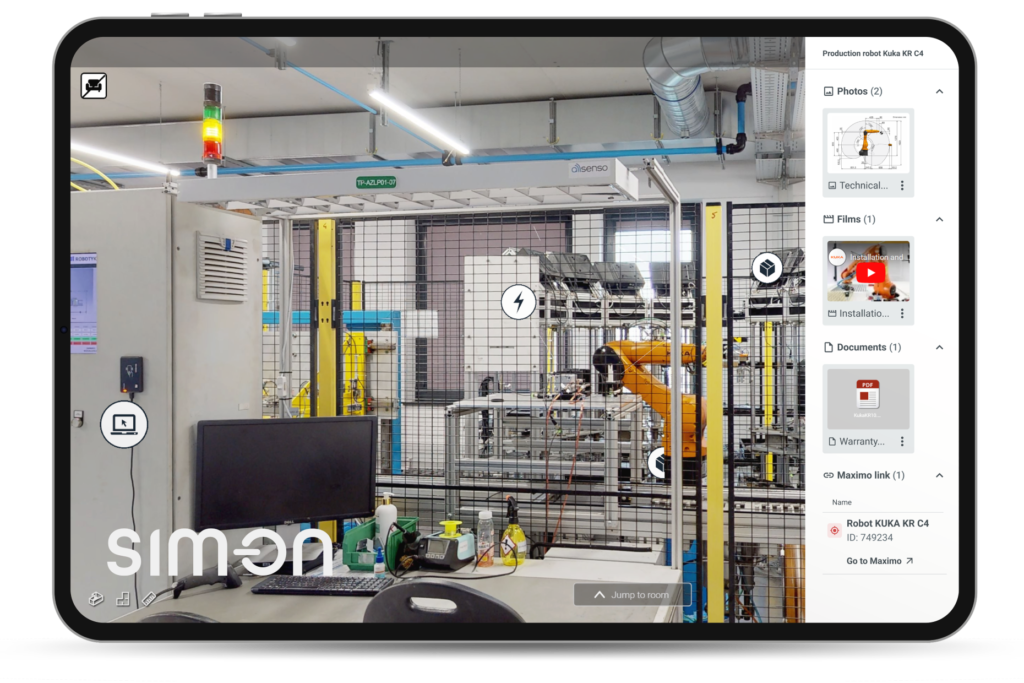

Connecting Maximo with the Digital Twin enables visualization of assets and data in their actual spatial context. You can view the physical layout of machines, infrastructure, or resources on 3D maps, which facilitates understanding of dependencies and flows in the operational environment.

Easier Problem Location:

In case of a failure or inspection need, employees can quickly and precisely locate problematic elements in the real environment, reducing response time and minimizing the risk of errors.

Optimized Maintenance Planning

Predictive Maintenance

By integrating data from Maximo (e.g., failure history, inspection reports) with the Digital Twin model, more accurate predictions of failures and maintenance planning based on spatial data become possible. Service schedules can be optimized based on precise information about the condition and location of assets.

Field Work Planning

Spatial visualization simplifies creating more efficient logistical plans for service teams, minimizing travel time and maximizing operational efficiency.

Realistic Simulation of Operations and Processes

Scenario Simulations

The Digital Twin can test different operational or maintenance scenarios without disrupting activities. It allows for resource optimization simulations, failure responses, or planned downtimes, helping companies better prepare for various situations.

What-If Analysis

The Digital Twin model enables “what-if” analyses, allowing verification of potential decisions before they are implemented. For example, infrastructure setting changes can be simulated in the model before being executed in reality.

More Effective Risk Management

Better Infrastructure Condition Assessment

With Maximo connected to the Digital Twin, it’s easier to assess the technical condition of infrastructure, leading to more precise operational risk management. The real-time updated 3D model can consider environmental changes and enable faster response to potential threats.

Faster Anomaly Detection

Combining operational data with spatial models allows for detecting physical anomalies (e.g., building structure changes, new logistical obstacles) and taking corrective action quickly.

Increased Operational Efficiency

Real-Time Monitoring

The Digital Twin can be continuously updated with data from IoT systems and Maximo, enabling real-time monitoring of asset conditions. Users have full visibility of operations, allowing for faster and better decision-making.

Improved Team Collaboration

Integrating spatial visualization with Maximo allows different teams (e.g., technical, operational) to work in a unified environment, making information exchange easier and improving interdepartmental communication.

Simplified Complex Decision-Making Processes

Ease of Data Analysis

Complex technical data from Maximo can be difficult to interpret in traditional tabular formats. Visualization in the Digital Twin model simplifies analysis and supports decision-making based on the actual picture of the work environment.

Improved Analytics

Using advanced analytics tools on combined Maximo and Digital Twin data enables better insights to support both short-term operations and strategic asset management decisions.

Greater Precision in Resource Management

Location Data Accuracy

Integrated spatial visualization eliminates issues with location inaccuracies. Users can be confident they are working with precise data, which is especially important when managing large infrastructures spread over wide areas (e.g., industrial plants, and power grids).

Cost Reduction

Resource Optimization

With a better understanding of infrastructure and processes, more efficient resource allocation is possible, leading to significant cost savings.

Reduced Failures and Downtime

Predictive analytics and improved maintenance can reduce the number of unexpected failures, lowering the costs associated with repairs and downtime.

The integration of the Maximo system with the SIM-ON platform offers numerous benefits, from improving operational efficiency, better planning and monitoring, to optimizing maintenance and reducing costs. By combining Maximo’s management data with the ability to quickly locate them in a spatial model, companies can achieve higher control over their infrastructure and manage resources more effectively in real-time.

Learn more on Aiut website: https://aiut.com/rozwiazania/it-dla-przemyslu/it-eam-cmms/digital-twin/